Top 5 Tips: The Maintenance Module – Part 1

The Maintenance Module is an excellent tool for managing your department’s apparatus and equipment. Recently, we’ve added new functionality to the module that allows you to schedule maintenance in the future and easily view maintenance items by category or even by a single piece of equipment.

Below are the first three tips to help you get the most out of the Maintenance Module. The last two tips will appear in my next blog article.

Tip #1: Equipment Categories

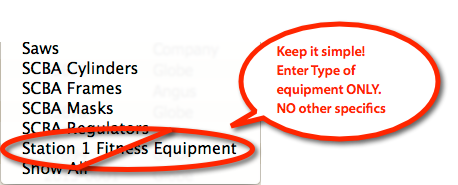

This is a two-for-one bonus…First tip: Always create your equipment categories solely by equipment type. Never create a category based on the location of the equipment. I’ve seen this happen occasionally and it just creates a mess.

Second, consider grouping related items with a prefix. For example, if you are creating categories for turnout pants, turnout coats, helmets, etc., use the prefix “PPE†so that similar items are clustered together in the dropdown list when you go to search for equipment that is part of an ensemble or is a similar type of equipment with a different characteristics. Here’s an example of a tidy equipment list:

Tip #2: Assigning Equipment to a Person, Apparatus, or Station

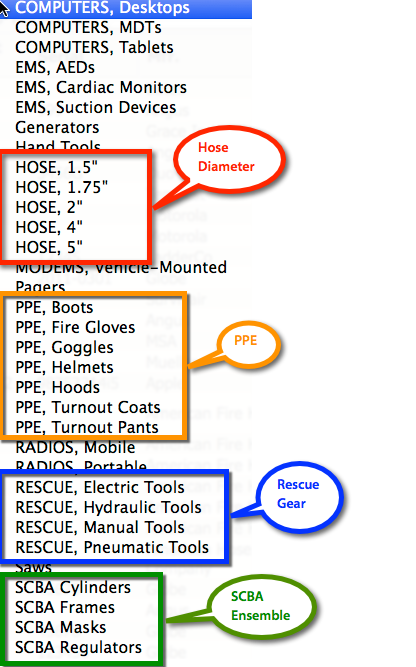

During training sessions, I often get asked about the best way to assign equipment –“Should I assign a piece of equipment to both a station and apparatus?†“What about assigning to personnel?†Here are a few recommendations that seem to work pretty well.

- In most instances, it’s best to assign a piece of equipment to just one of the three possibilities: A person, an apparatus, or a station.

- If the equipment is PPE or specifically assigned to an individual, then simply select that person.

- If it’s on a truck, then assign it just to the apparatus.

- If it’s in a cabinet in the station, then assign just it to that station.

If needed, you can always assign a piece of equipment to more than one of the three choices. A good example is fire hose. If you have a firefighter responsible for testing all the 1 ¾†hose, then you could assign those sections of hose to him as well assigning them to their actual physical location.

This comes in handy when you want to generate a quick list of the all hose sections the firefighter needs to test (Report #1515 – Equipment List & Maintenance History for Assigned Personnel). Remember, how you assign equipment will directly affect the reports you generate from the Maintenance Module.

Tip #3: Emailing Work Orders

Once a work order is requested, a supervisor can assign and email that work order to an individual or an outside vendor.

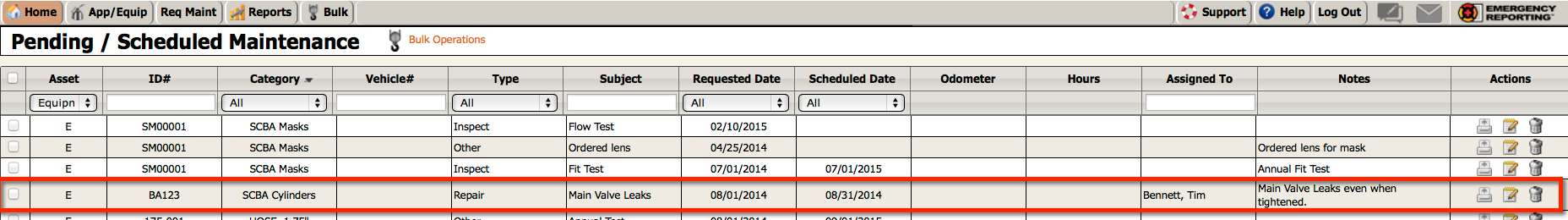

- From the Pending/Scheduled Maintenance Grid, simply double-click on the maintenance item or click the Edit icon to see its details:

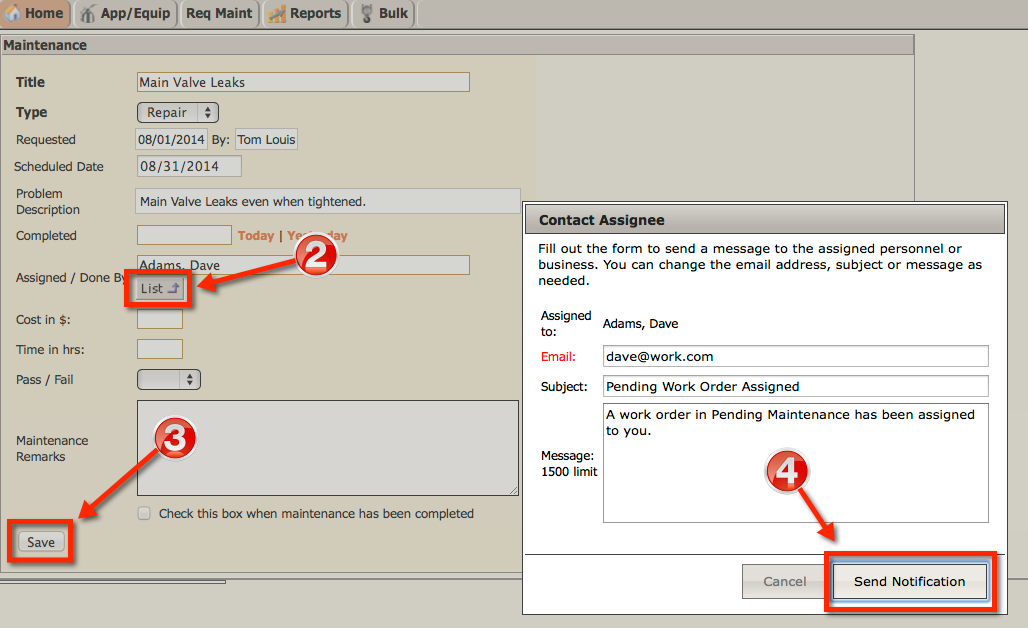

- Next, click the List button. A pop-up will appear with names of personnel and vendors. Choose whom you wish to assign the maintenance order.

- Then click Save. At this point, you’ll see a dialog box appear where you can edit an email message to the recipient about the work order. (Email addresses will auto-fill if the person’s email address is in the Admin Module Personnel List).

- Click the Send Notification button. The recipient will receive an email with a link that will take them directly to the maintenance request. Pretty cool!

Stay tuned for Part 2 of The Top 5 Tips: Maintenance Module.